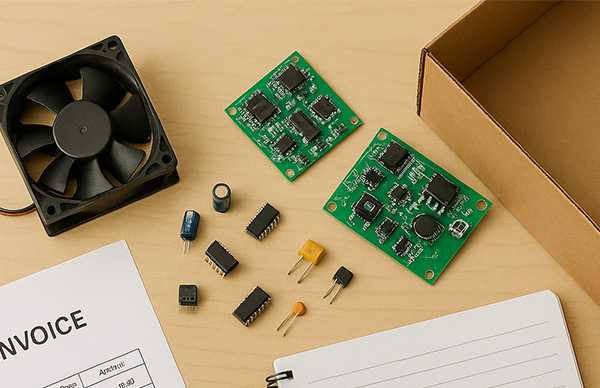

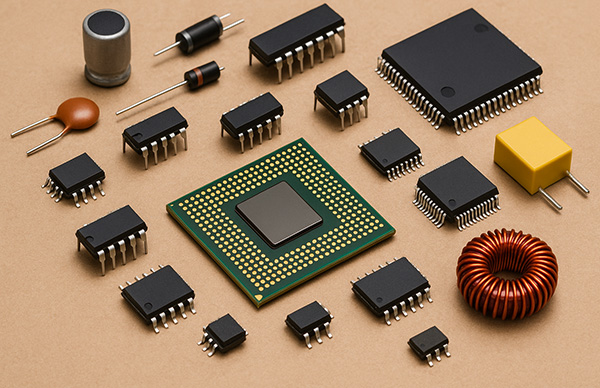

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, offering enhanced precision, efficiency, and scalability. Since its inception in the 1960s, SMT has grown to become the dominant method for assembling electronic components onto printed circuit boards (PCBs). Initially developed as an alternative to Through-Hole Technology (THT), SMT has enabled higher component densities, automated assembly, and cost-effective production.

By the 1980s, SMT had become widely adopted, driving advancements in pick-and-place machines, solder paste printers, reflow ovens, and inspection systems. These innovations have significantly improved manufacturing speed, reduced costs, and enhanced the reliability of electronic devices.

Perceptive Components’ SMT Solutions

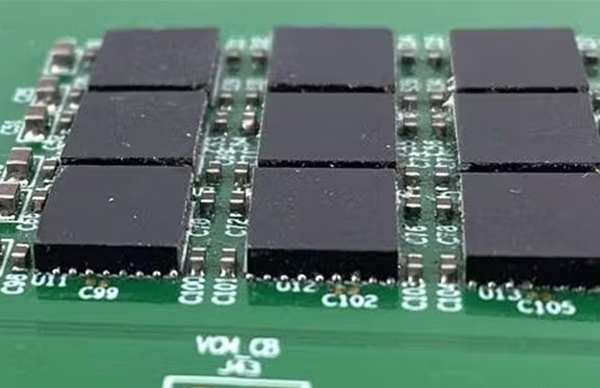

Perceptive Components is at the forefront of SMT services, providing cutting-edge solutions for high-precision electronic assembly. Our comprehensive SMT capabilities include:

Solder Paste Printing – Ensuring optimal solder deposition for strong component bonding.

Automated Pick-and-Place – High-speed, precision placement of SMT components onto PCBs.

Reflow Soldering – Controlled heating for superior solder joint formation and mechanical stability.

Automated Optical Inspection (AOI) – Detecting assembly defects with high accuracy.

X-ray Inspection – Identifying hidden defects, particularly in solder joints and Ball Grid Array (BGA) components.

Advanced PCB Handling Systems – Streamlining production with efficient material transfer solutions.

Advantages of Choosing Perceptive Components'SMT Services

Miniaturization – Enabling the production of compact, lightweight electronic devices.

High-Speed Production – Reducing assembly time through automation and advanced SMT techniques.

Enhanced Reliability – Ensuring superior electrical performance and mechanical integrity.

Cost Efficiency – Minimizing material waste and labor costs through automated processes.

Scalability – Supporting both low-volume prototyping and large-scale production while maintaining high-quality standards.

Market Trends and Growth Drivers

The SMT industry continues to expand, driven by several key trends:

Growing Demand for Consumer Electronics

The widespread adoption of smartphones, tablets, wearables, and smart home devices has fueled the need for high-performance SMT solutions. Manufacturers are investing in high-speed, high-precision SMT equipment to meet increasing demands.

Advancements in 5G and IoT Technologies

The rollout of 5G networks and the expansion of the Internet of Things (IoT) have increased the demand for sophisticated PCBs. Perceptive Components’ SMT services cater to the production of high-density circuit boards essential for these technologies.

Rise of Automotive Electronics

Modern vehicles are becoming more electronically advanced with features such as Advanced Driver Assistance Systems (ADAS), infotainment, and electric vehicle (EV) components. This shift is driving the need for reliable SMT assembly solutions.

Integration of Automation and Industry 4.0

Our SMT services incorporate AI-driven automation, robotics, and real-time data analytics to enhance efficiency, predictive maintenance, and overall operational performance.

Sustainability and Regulatory Compliance

Perceptive Components prioritizes environmentally friendly manufacturing processes, offering lead-free soldering and energy-efficient SMT equipment to comply with global sustainability regulations.

As technology continues to evolve, Perceptive Components remains committed to delivering SMT solutions. Emerging trends such as AI-driven inspection systems, flexible PCBs, and 3D-printed circuit integration are poised to reshape the SMT landscape. For SMT assembly, please contact Perceptive.

Additionally, the adoption of smart manufacturing and digital twin technology will further optimize efficiency, reduce defects, and enhance customization capabilities. With continued advancements in healthcare, aerospace, and telecommunications industries, SMT will remain a key driver of innovation.