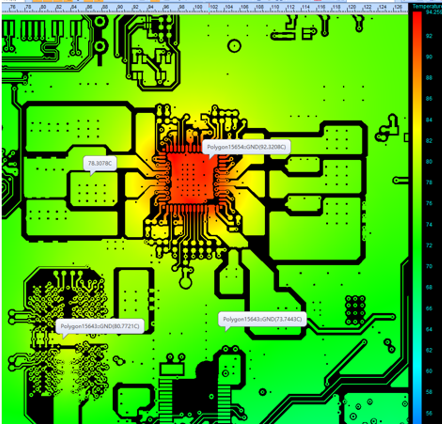

With the rapid development of high frequency, high speed and integrated circuit technology of electronic devices, the total power density of electronic components has increased significantly while the physical size has become smaller and smaller, and the heat flux density has also increased. The high temperature environment affects electronic components. device performance, which requires more efficient thermal control of it.

The problem of efficient heat dissipation of electronic components is affected by the principles of heat transfer and fluid mechanics. The heat dissipation of electrical devices is to control the operating temperature of electronic equipment to ensure the temperature and safety of its work, which mainly involves different aspects such as heat dissipation and materials. At this stage, the main heat dissipation methods are mainly natural, forced, liquid, refrigeration, dredging, and heat pipes.

1. Natural heat dissipation or cooling method

The natural heat dissipation or cooling method is to control the temperature in the way of heat dissipation from the surrounding environment through local heating devices without accepting any external auxiliary energy under natural conditions. The main methods are heat conduction, convection and radiation concentration. The main applications are convection and natural convection.

Among them, natural heat dissipation and cooling methods are mainly used in electronic components with low temperature control requirements, and low power consumption equipment and components with relatively low heat flux density. This approach can also be used in sealed and densely packed devices without the need to apply other cooling techniques.

2. Forced heat dissipation or cooling method

The forced heat dissipation or cooling method is a way to speed up the air flow around the electronic components and take away the heat by means such as fans. This method is relatively simple and convenient, and the application effect is remarkable. In electronic components, if the space is large enough to allow air to flow or install some heat dissipation facilities, this method can be applied.

3. Liquid cooling heat dissipation method

The method of applying liquid cooling in electronic components for heat dissipation is a heat dissipation method formed based on chips and chip components. Liquid cooling can be mainly divided into direct cooling and indirect cooling.

The indirect liquid cooling method is that the applied liquid coolant is in contact with the electronic components directly. Through the intermediate media system, auxiliary devices such as liquid modules, thermal conduction modules, jet liquid modules and liquid substrates are used in the emitted thermal elements. to transmit.

The direct liquid cooling method can also be called immersion cooling method, which is to directly contact the liquid with the relevant electronic components, absorb heat through the coolant and take away the heat, mainly in some applications with relatively high heat consumption volume density or high temperature environments device.

4. Refrigeration method of heat dissipation or cooling method

The cooling methods of heat dissipation or cooling methods mainly include phase change cooling of refrigerants and Pcltier cooling. The methods adopted are different in different environments, and should be reasonably applied based on the actual situation.

The phase change cooling of the refrigerant is a way to absorb a large amount of heat through the phase change of the refrigerant, which can cool electronic devices in some specific occasions. The general state is mainly to take away the heat in the environment through the evaporation of the refrigerant, which mainly includes two types of volume boiling and flow boiling. In some computer systems with relatively high power, cryogenic technology can be applied, which can not only improve the cycle efficiency, but also have a wide range of refrigeration quantities and temperature ranges. The structure of the entire machine equipment is relatively compact and the cycle efficiency is relatively high. higher.

Pcltier refrigeration dissipates heat or cools some conventional electronic components by means of semiconductor refrigeration, which has the advantages of small size, convenient installation, strong quality, and easy disassembly. This method is also called the thermoelectric cooling method. It is through the Pcltier effect of the semiconductor material itself, and the direct current is formed through the action of different semiconductor materials in series to form a galvanic couple, which can absorb heat and release heat at both ends of the galvanic couple. , so that the cooling effect can be achieved.

5. Energy diversion methods in heat dissipation or cooling

The heat dissipated by the electronic device is transferred to another environment through a heat transfer element that transfers the heat. In the process of electronic circuit integration, high-power electronic devices are gradually increasing, and the size of electronic devices is getting smaller and smaller. It is required that the heat dissipation device itself has certain heat dissipation conditions, and the heat dissipation device itself must also have certain heat dissipation conditions.

Because the heat pipe technology itself has certain thermal conductivity characteristics and good isothermal characteristics, it has the advantages of variable heat flux density, good constant temperature characteristics, and can quickly adapt to the environment in applications. It is widely used in the heat dissipation of electronic and electrical equipment. It can effectively meet the characteristics of flexibility, high efficiency and reliability of the heat dissipation device, and is widely used in the cooling of electrical equipment, electronic components and the heat dissipation of semiconductor components at this stage.

6. Heat pipe cooling

A typical heat pipe consists of a tube shell, a porous capillary wick and a working medium. After the working medium absorbs the heat generated by the heat source from the evaporation section in a vacuum state and evaporates, it quickly flows to the condensation section under the action of a small pressure difference, and releases latent heat to the cold source to condense into a liquid condensate, which is then capillary suction in the wick. Under the action of force, it returns from the condensation section to the evaporation section, and then absorbs the heat generated by the heat source.

In this way, the heat is continuously transferred from the evaporation section to the condensation section. The biggest advantage of a heat pipe is that it can transfer a large amount of heat with a small temperature difference, and its relative thermal conductivity is several hundred times that of copper, which is called a 'near superconductor', but any heat pipe has a heat transfer limit. When the calorific value at the evaporation end exceeds a certain limit value, the working medium in the heat pipe will be completely vaporized, resulting in the failure of the heat pipe due to interruption of the circulation process.