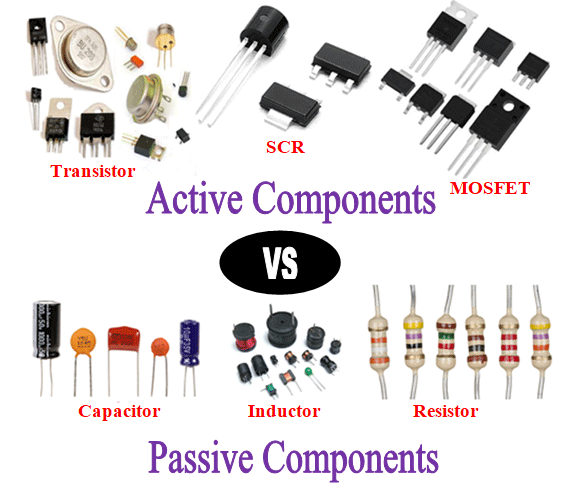

Electronic components drive almost everything in our modern lives, but as long as there are parts buyers, counterfeiters will try to stay in business. Some counterfeit component assemblers and warehousing operations may consider adding component testing capabilities and services to identify fakes prior to assembly. Here's how to test and verify components in batch orders.

How to Quickly Test and Inspect Component Batches?

Electronic component batches can contain thousands of individual parts. Sometimes these parts are packaged on tape and reel, sometimes on pallets, and sometimes in tubes. Depending on the size of the lot, the number of different components involved, and the type of component, it may not be possible to test every component in the PCB.

Here are some key points to consider before starting a specific test and inspection program:

Focus on the highest risk components, such as expensive integrated circuits

Focus on repackaged parts, as repackaging may imply tampering

Focus on parts sourced outside authorized channels

For large batches, use statistical methods and select meaningful sample sizes

With that in mind, start by looking at some simple tests that will identify most mishandled or fraudulent components.

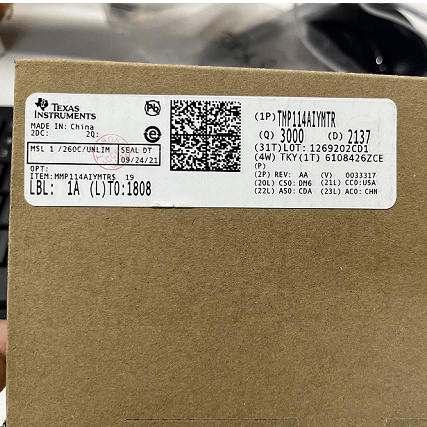

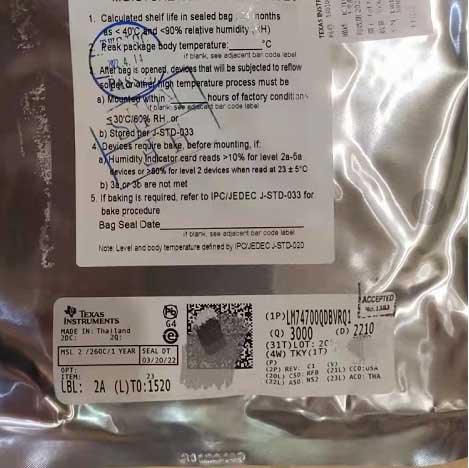

Packaging Inspection

The first place to check for component packaging is especially storage and transportation packaging. Components should be properly packaged to protect them from the environment and allow for long-term storage. This involves the use of moisture-proof bags, desiccants, anti-static materials, and correct dates on the packaging. Improper packaging materials or reuse of packaging materials may be signs of mishandling and may require a more in-depth inspection of the component.

Repackaged components that have been vacuum sealed will be clearly marked with the location of the sealer heating

If the packaging looks incorrect, further inspection or remediation may be required. Sometimes packaging problems are obvious; throwing parts into cardboard boxes is a clear example of mishandling. A closer inspection of the component directly may be required, the part may need to be baked according to the MSL of the part, or even electrical testing may be required for some parts.

Physical Inspection

A visual inspection of the part is also required after opening the package. Be sure to check several spots on the package that may indicate that the part is recycled or counterfeit:

Part number

Date code

Potential customer quality

Presence of corrosion

Any damage or markings on the package

Spots of staining

All of these points can be visually inspected with a magnifying glass or microscope, and some can even be inspected automatically with an optical system.

Parts that do not pass physical inspection will usually have obvious defects such as missing labels, missing date codes, old date codes or severe corrosion. This is usually associated with recycled or reclaimed parts. If parts remain suspicious, a number of non-destructive and functional tests can be performed.

Non-Destructive Testing

This refers to a category of possible test mechanisms that can help identify defective parts without damaging the assembly under test. The most common method of inspecting components using equipment readily available in PCB assembly facilities is X-ray inspection. Using an X-ray machine, chips can be seen in the component package, and X-ray imaging is fast enough and accurate enough to quickly look at a small sample and characterize a batch of components. However, if the component passes this test, no further inspection or testing may be required.

Circuits Testing

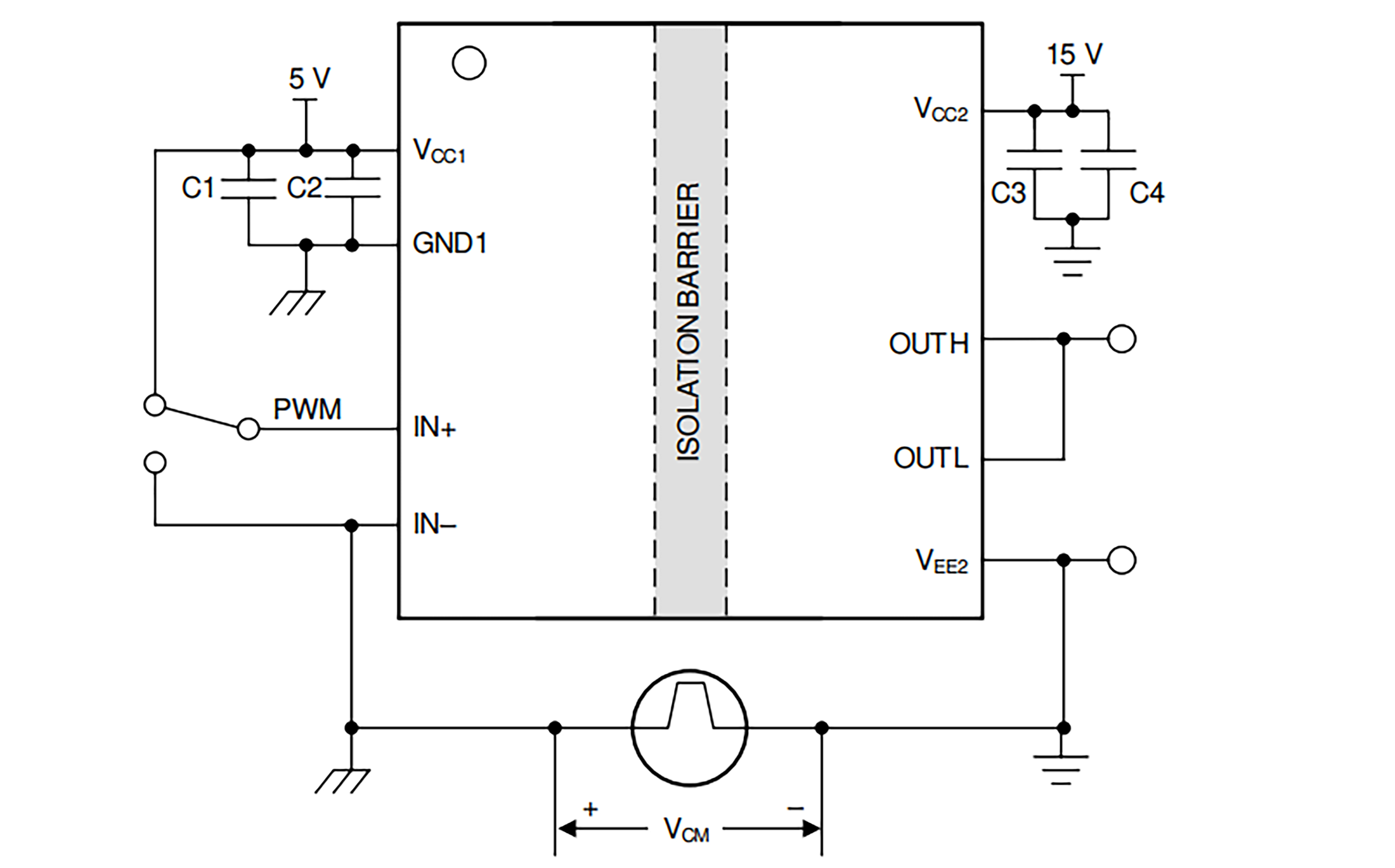

Another way to test incoming components is to build fixtures with test circuits. Some datasheets provide sample test circuits that can be used to verify that the components are real and function properly. An example is shown below for Texas Instruments part number UCC5350.

These test circuits always need to be custom built, usually on a perforated board or breadboard, and then connected to an automated test program. Simply checking the pin output levels is much easier than monitoring the pins over time.

Test fixtures will provide the best results, but because of the investment involved, they should be reserved for the highest-value, highest-risk components. Dedicated ASICs for which there are no alternatives and some processors are potential candidates for evaluation using test circuits. Some RF components, such as off-the-shelf modules or PCB-mounted assemblies, can also be tested using automated fixtures, although the test and measurement equipment required to do so can be very expensive.

The RF filter modules like this bandpass filter can be tested with automated test equipment.

If you want to avoid the hassle of maintaining a parts test and quality control program, make sure you stick with the authorized distributor channel. Authorized distributors or purchasing directly from the manufacturer will eliminate the need for these test procedures. To help you find the parts you need for your build, be sure to use the right data source with complete supply chain visibility!

Whenever you need to find a reliable source for electronic components in your BOM, visit Perceptive to create a component order. You can also find suggested alternatives as well as up-to-date distributor pricing data, part inventory, and part specifications on Perceptive's homepage.

————————

About Perceptive Components Limited

We are one of the world's leading distributors of semiconductor and electronic components. With 21 years of business experience in the electronic components industry, we have in-depth cooperative relations with thousands of brand manufacturers and agents, focusing on TI, Microchip, NXP, Infineon, Intel, onsemi, ST, Micron.

To learn more about Perceptive, visit perceptive-ic.com.