With the rapid development of information technology, integrated circuit (IC) chips have become the core components of modern technology products, and their performance, quality and reliability directly affect the operation of the entire system. Due to the trend of miniaturization and complexity of IC chips, traditional inspection means can no longer meet the demand for accurate identification of internal structure and defects. At this time, X-ray inspection equipment as a non-destructive and efficient detection technology came into being, becoming an important tool for IC chip quality control.

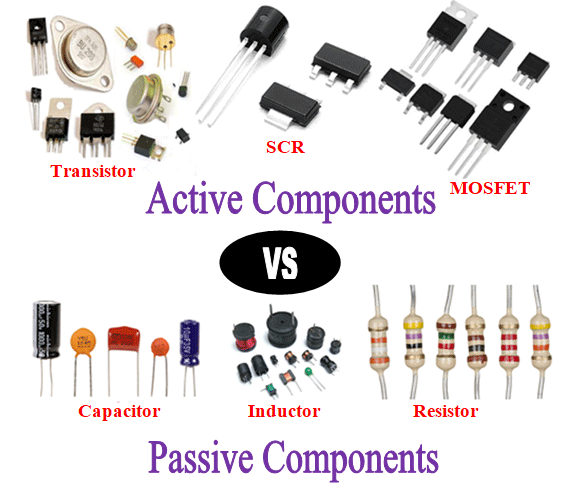

First of all, the microscopic characteristics of the IC chip determine that it must use X-ray inspection equipment. The line width of modern IC chips has been reduced to the nanometer level, and the interior contains hundreds of millions of transistors, wires and other microstructures, which can not be directly observed under a conventional optical microscope. X-ray inspection equipment, however, utilizes the penetrating properties of X-rays, which can penetrate through the packaging material to achieve perspective imaging of the internal microstructure of the chip, and accurately capture potential defects such as open circuits, short circuits, voids, contamination, poor soldering and other issues.

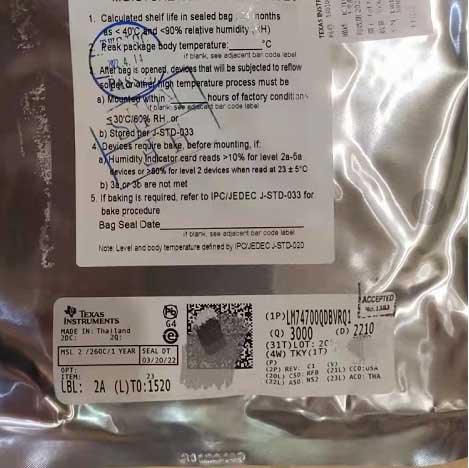

Secondly, X-ray inspection equipment has unique advantages for IC chip inspection after packaging. IC chips are usually encapsulated after completion of manufacturing to protect them from environmental influences and ensure electrical connections. However, various problems during the encapsulation process, such as soldering defects on solder balls or pins, can also seriously affect chip performance. X-ray inspection technology can effectively detect and analyze internal defects in packaging by projecting X-rays at different angles and generating three-dimensional images from multiple dimensions.

Furthermore, X-ray inspection equipment helps to improve production efficiency and product quality. The automated X-ray inspection system can complete fast and accurate inspection of a large number of IC chips in a short period of time, which greatly improves the inspection efficiency and production capacity of the production line. At the same time, timely detection of problems to avoid defective products into the market, a strong protection of product quality and brand reputation.

To summarize, the IC chip using X-ray inspection equipment for testing, because it has high precision, high efficiency and non-destructive features, can effectively solve the chip microstructure inspection problems, to protect product yields and reliability. In the future, with the continuous breakthroughs in chip technology, X-ray inspection technology will be continuously upgraded and optimized to provide more powerful and comprehensive technical support for IC chip quality control.

————————

About Perceptive Components Limited

We are one of the world's leading distributors of semiconductor and electronic components. With 21 years of business experience in the electronic components industry, we have in-depth cooperative relations with thousands of brand manufacturers and agents, focusing on TI, Microchip, NXP, Infineon, Intel, onsemi, ST, Micron.

To learn more about Perceptive, visit perceptive-ic.com.