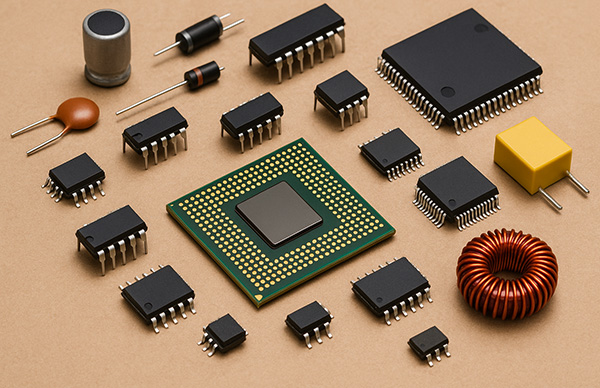

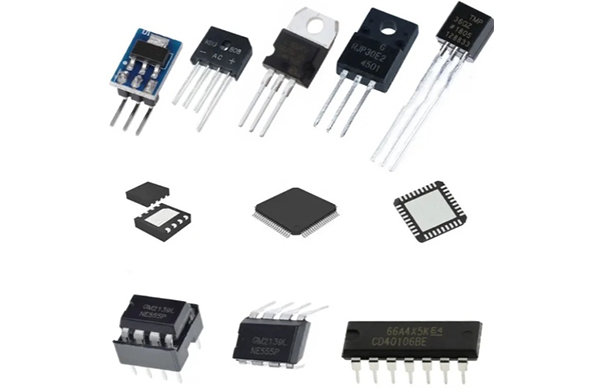

In the world of electronic components procurement, the importance of selecting the right supplier cannot be overstated. A supplier is not just a vendor; they play a crucial role in shaping the quality, cost, and efficiency of your supply chain. For procurement professionals, the decision to partner with a supplier involves much more than just securing the lowest price; it requires careful consideration of various factors that can have long-term effects on the success of your operations.

This article explores the key factors that should influence your decision when choosing an electronic components supplier, offering practical advice to help you make an informed and strategic choice.

1. Quality Assurance and Certifications

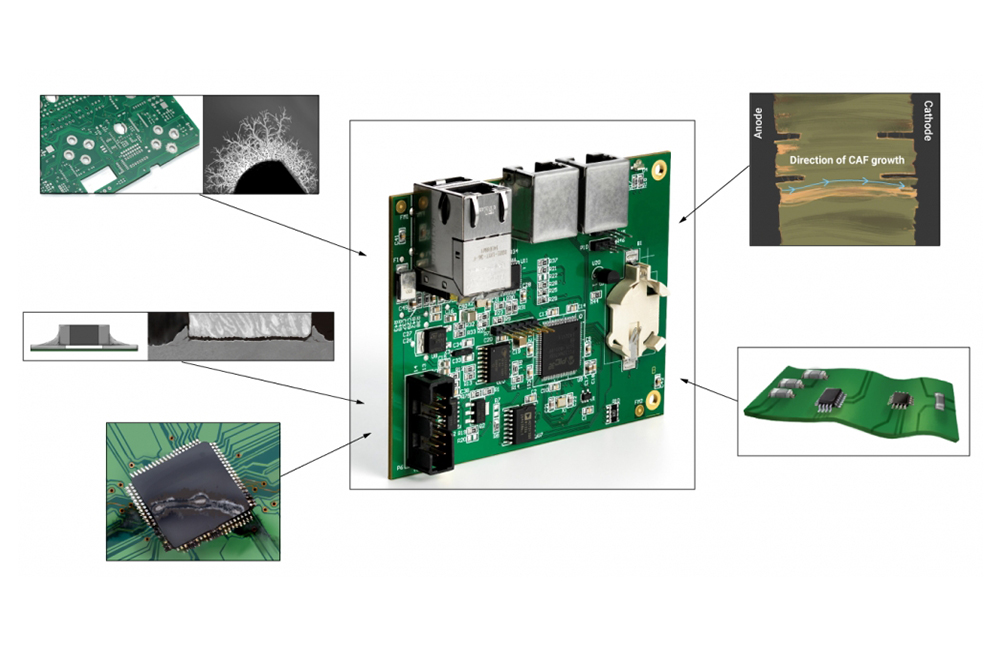

When it comes to sourcing electronic components, quality is paramount. Substandard components can lead to product failure, safety issues, and costly recalls. Therefore, it is essential to partner with suppliers who have stringent quality control measures in place. Look for certifications such as ISO 9001 (for quality management systems), RoHS (Restriction of Hazardous Substances), UL (Underwriters Laboratories), or IATF 16949 (for automotive components). These certifications indicate that the supplier adheres to international standards and practices that ensure the components meet the required quality benchmarks.

Additionally, request detailed documentation of the supplier's quality control process, testing methodologies, and performance history. A supplier with a track record of delivering consistent quality is invaluable.

2. Supplier's Reputation and Track Record

A supplier's reputation is often an indicator of their reliability and professionalism. When evaluating potential suppliers, take the time to research their market standing. Companies with a solid reputation are likely to provide dependable service, meet deadlines, and resolve any issues that arise swiftly.

Look for suppliers who have worked with well-known companies or have a strong client portfolio. Customer testimonials, case studies, and reviews can offer valuable insights into the supplier's capabilities.

Tip: Consider reaching out to businesses in similar industries that have previously worked with the supplier. Their feedback can provide a clearer picture of what you can expect in terms of product quality and customer service.

3. Lead Time and Delivery Performance

Timeliness is often a critical factor in the procurement process. In the fast-paced world of electronics, delays in component delivery can halt production and lead to costly delays in product launches. Assess the supplier's lead time and ability to deliver on schedule.

Request detailed information on their typical delivery timelines, and inquire about their processes for handling urgent orders. A supplier with a proven ability to meet deadlines will be crucial to maintaining the continuity of your operations.

Tip: Review their delivery performance metrics and ask for references from customers who have similar time-sensitive needs. This will give you a clear understanding of how well they perform under pressure.

4. Inventory and Supply Chain Management

A supplier's inventory management system is crucial for ensuring the smooth flow of components throughout the supply chain. Look for suppliers who have a well-managed inventory system, ensuring they can quickly fulfill your orders even during periods of high demand.

Assess whether the supplier has the capacity to maintain consistent stock levels, handle fluctuations in demand, and provide transparency in their inventory practices. A reliable supplier should also offer tracking mechanisms that allow you to monitor the status of your orders in real-time.

Tip: Investigate their warehouse capacity and inventory turnover rates. Ask about their processes for managing out-of-stock situations and whether they offer expedited shipping options in case of emergencies.

5. Price Transparency and Cost Efficiency

While price is an important factor in any procurement decision, it should not be the sole deciding element. The lowest price often comes with hidden costs that may undermine the value of the deal. Instead, focus on the total cost of ownership (TCO), which includes not only the purchase price of the components but also additional expenses such as shipping, taxes, handling, and warranty or return costs.

Request detailed quotes from multiple suppliers, making sure all costs are transparent and clearly explained. Compare these costs with the supplier's overall value proposition, taking into account their product quality, customer service, and reliability.

Tip: Beware of suppliers offering significantly lower prices than their competitors. This may indicate a compromise in quality, delivery performance, or service. Balance cost with other critical factors to ensure long-term value.

6. Innovation and Technological Capabilities

The electronics industry is constantly evolving, and innovation plays a key role in maintaining competitive advantage. Suppliers who invest in research and development (R&D) and offer cutting-edge products can help you stay ahead of the curve. When selecting a supplier, consider their ability to provide innovative solutions that align with your product development goals.

Tip: Inquire about the supplier's involvement in R&D initiatives, their product development process, and access to emerging technologies. Suppliers with a strong technological foundation are more likely to offer future-proof solutions and better support your evolving needs.

7. Customer Support and Relationship Management

Effective communication and support are essential when working with any supplier. In the fast-moving world of electronics, issues can arise at any point in the supply chain. A supplier who provides excellent customer service can help resolve problems quickly, minimizing disruptions to your operations.

Choose a supplier who offers clear communication channels, timely responses, and dedicated support teams. A strong, proactive relationship with your supplier can be a significant advantage in managing challenges as they arise.

Tip: Assess the supplier's approach to customer service. How quickly do they respond to inquiries? Are they willing to offer technical support when needed? A supplier who invests in customer service is likely to be a long-term partner you can rely on.

8. Sustainability and Ethical Practices

Sustainability has become a key consideration for businesses across industries, and the electronics sector is no exception. More companies are opting to work with suppliers who prioritize ethical sourcing, sustainable manufacturing practices, and environmentally friendly production methods.

Ensure that the supplier aligns with your sustainability goals and corporate social responsibility (CSR) standards. Suppliers who follow eco-friendly practices can contribute to enhancing your brand image and meeting regulatory requirements related to environmental impact.

Tip: Investigate the supplier's environmental policies, waste management practices, and sourcing transparency. A supplier with a strong sustainability track record will be better positioned to meet your company's growing demand for eco-conscious solutions.

Conclusion

Choosing the right supplier in the electronic components industry is a decision that requires careful thought and evaluation. By considering factors such as quality, lead time, price transparency, innovation, and customer support, procurement professionals can ensure they partner with a supplier who not only meets their immediate needs but also contributes to long-term business success. Remember, the right supplier is a strategic partner who will help you navigate challenges, seize opportunities, and drive innovation in the rapidly evolving electronics landscape.

Perceptive provides a one-stop solution for all your electronic component needs. If you're concerned about choosing the right supplier, leave it to us—we ensure quality, reliability, and seamless procurement.