Texas Instruments' new BQ25790 and BQ25792 buck-boost battery charger IC solutions offer maximum power density as well as general purpose and fast charging with up to 97 percent efficiency. These ICs support low quiescent current and provide flexibility for USB Type-C, the entire input voltage range (3.6 V to 24 V) of USB Type, can charge one to one battery in series up to four batteries, and operate across the input Charge current up to 5 A is available in the voltage range (3.6 V to 24 V). -C power delivery (USB PD) and wireless applications. These new solutions will be used in small personal electronic devices, portable medical equipment and building automation applications.

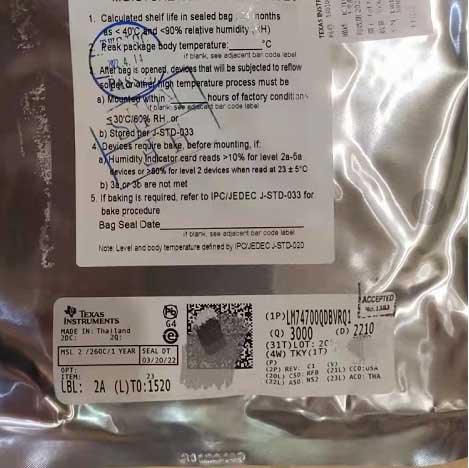

TI's buck-boost IC

Universal charging allows charging via car adapters or USB PD adapters, bringing a new level of flexibility and convenience to various devices, especially in the medical field. Bi-directional charging supports on-the-go (OTG) charging. Designers are looking for solutions that extend battery runtime and utilize maximum battery capacity while charging efficiently and reducing heat dissipation to minimize power dissipation within the charger IC. TI's new family of integrated buck-boost charger ICs, including the BQ25790 and BQ25792, offer greater flexibility using the USB PD input when charging 1S-4S batteries with an input voltage range of 3.6V to 24V. These devices use a very low power charging IC to extend battery run time during operation and to conserve battery power when the application is not in use. In addition to ultra-low power consumption, the charger is equipped with a self-top timer that allows additional charging after the normal charging cycle, allowing the battery to be charged to its maximum capacity. The BQ25790 and BQ25792 multi-cell buck-boost chargers use less than 1 µA of quiescent current. Combined with the extremely low 8mΩ battery FET resistance, engineers can further extend battery run time in applications that require extended operation (Figure 1).

Figure 1: BQ25790 Block Diagram

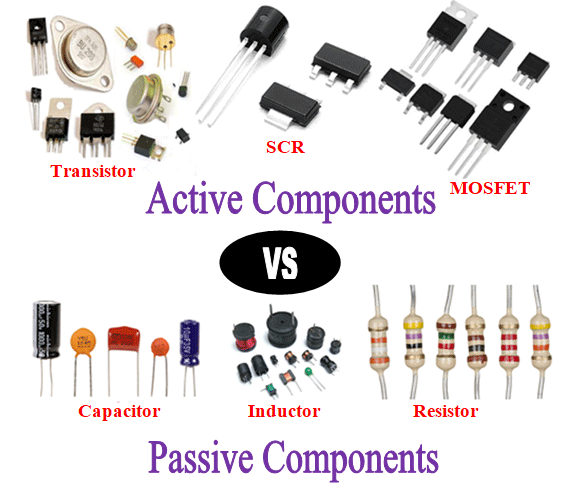

The new buck-boost charger fully integrates the following components: metal oxide semiconductor field effect transistor (MOSFET) , battery FET, current sensing circuit and dual input selector switch. The reduction in component count is especially important for applications such as smart speakers, which are getting smaller and cheaper as market adoption increases.

There is always a trade-off in component integration in terms of area, cost, and performance. Buck-boost chargers have become more popular in recent years due to their ability to charge batteries from almost any input source and cater to Type-C and PD USB adapters. A key advantage of widespread USB Type-C adoption is a realistic path to a universal adapter and corresponding reduction in electronic waste. A high power density buck/boost charger should not only integrate a general-purpose charging module, but also integrate other modules such as DC/DC converters to simplify system design. Figure 2 shows the system block diagram of the USB PD charging solution.

Figure 2: Block diagram of a USB PD charging solution

When the adapter is not present, the DC/DC converter discharges the battery to create the VBUS regulated voltage and power external devices. In the absence of an adapter, the back-to-back MOSFETs in the discharge power path will conduct, switching the output voltage U3 to VBUS and maintaining the VBUS voltage. This keeps the DC/DC converter on all the time. As part of the input overvoltage and overcurrent protection circuitry, control logic and driver circuitry for the external back-to-back MOSFETs are also integrated in the charger.

Control logic and driver circuitry for the external back-to-back MOSFETs are also integrated into the charger as part of the input overvoltage and overcurrent protection circuitry. These functions eliminate elements from the block diagram that support input power path management and input current sensing.

To support Fast Role Swap (FRS) for Type-C USB ports, the integrated buck-boost charger implements a new backup mode that monitors the VBUS voltage. A drop in VBUS voltage below a preset threshold indicates that the adapter has been removed. FRS is a major new feature of USB PD 3.0, where a powered device can quickly change its power role to become an energy consumer in order to maintain a consistent data connection. FRS helps prevent any data loss that occurs when power is accidentally removed from the device (Figures 3 and 4).

Figure 3: USB Type-C FRS implemented with a single buck-boost charger

Figure 4: Buck-boost charger FRS from VBUS sink to VBUS source

fast charging

Limited battery life compromises the autonomy of smartphone users. No matter how good the latest smartphone batteries are, they're still limited in size. Manufacturers try to make phones more and more energy efficient, but these phones are still increasingly used in power-hungry applications. The upshot is that batteries often don't last well into the night if only charged once. Fast charging allows you to quickly restore your device's battery life using a few technical tricks. Battery chargers for fast charging also act on the voltage value, thereby significantly increasing the power output.

Charging standards are a complex mix of chemistry and physics, and since each standard has its limitations, incompatibility can become a problem in itself. When electricity flows, the smartphone battery charges. Higher current and higher voltage can charge the battery faster, but there is a limit to the number of batteries that can be used. Charge regulators (ICs) prevent dangerous inrush currents by regulating the overall current flowing into and out of the battery.

USB PD provides a useful alternative for fast and efficient charging in a wide range of applications. The output voltage range of USB PD can be adjusted for different battery-powered devices with different battery configurations to take advantage of the 5W to 100W (20-V/5-A) power spectrum of USB PD.

It should be noted that the performance and functionality of an integrated circuit solution depends on the design and manufacturing quality of the chip itself, as well as the matching degree of the circuit and power system. Therefore, when using this solution, it needs to be selected and adjusted according to the actual situation to ensure that it can meet the needs of the equipment.

If you need products, please contact us through BOM!